QC Department

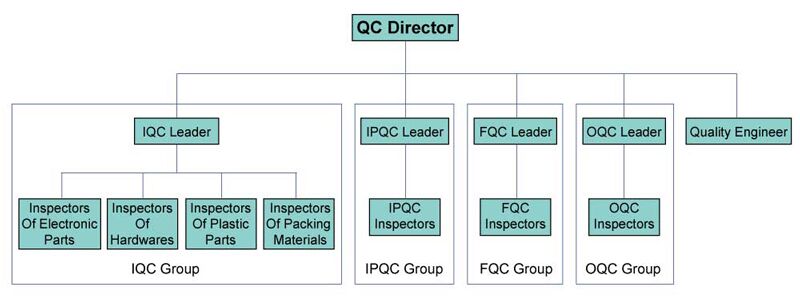

DK SONIC’s QC department is composed of five sections: Incoming quality control group(IQC), Input process quality control group(IPQC), finished quality control(FQC), outgoing quality control(OQC), quality engineer(QE). Please review the organizational structure chart below:

All products can not be dispatched without passing all checking processes by QC department. Please check the inspection procedures below:

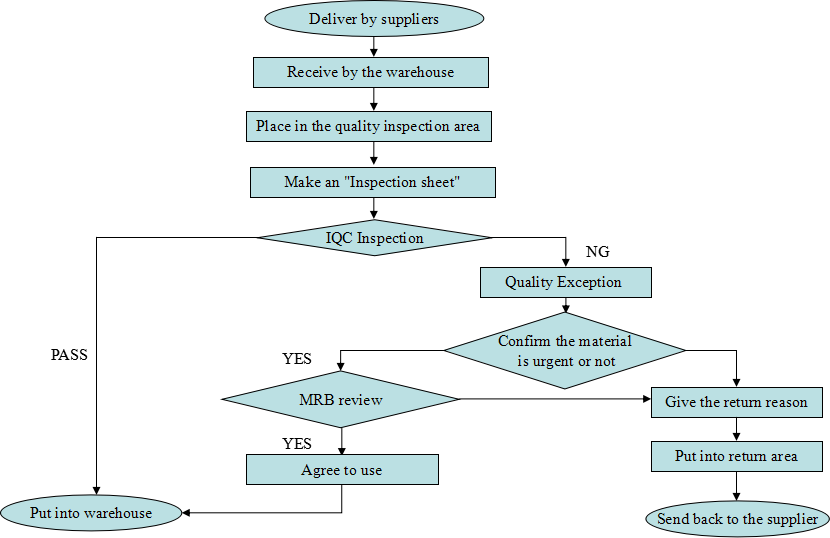

A. The incoming inspection process:

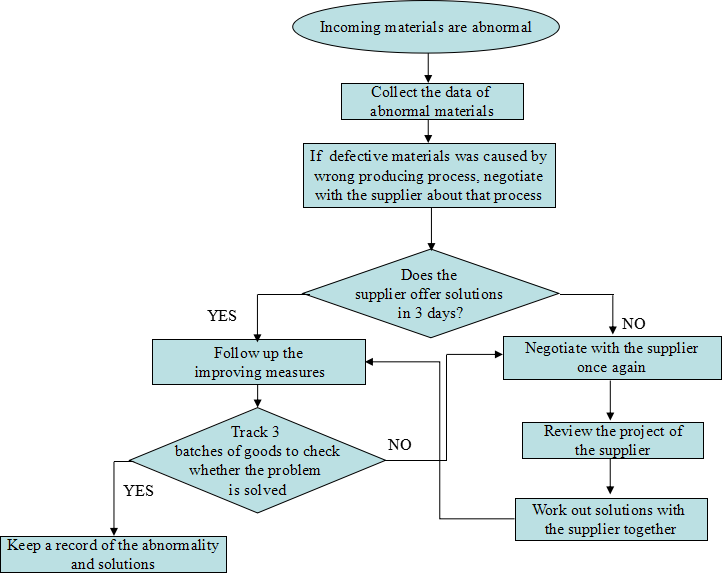

B. The handling process of abnormal materials:

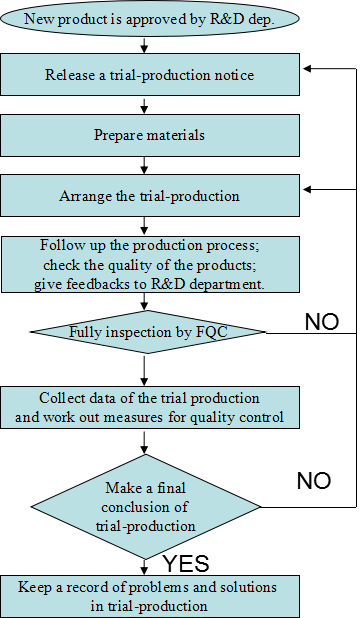

C. The QC process of the trial production of products

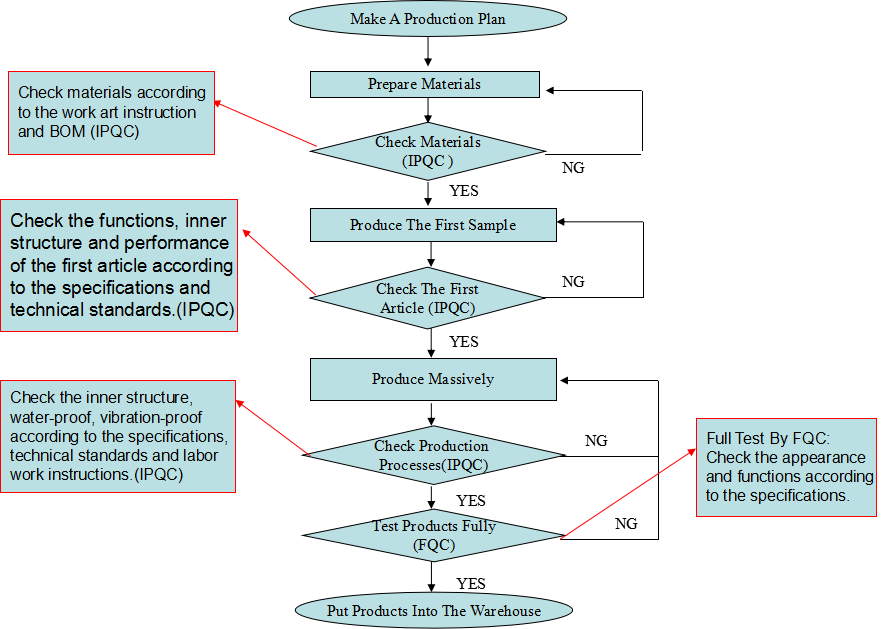

D. The inspection process of the first article:

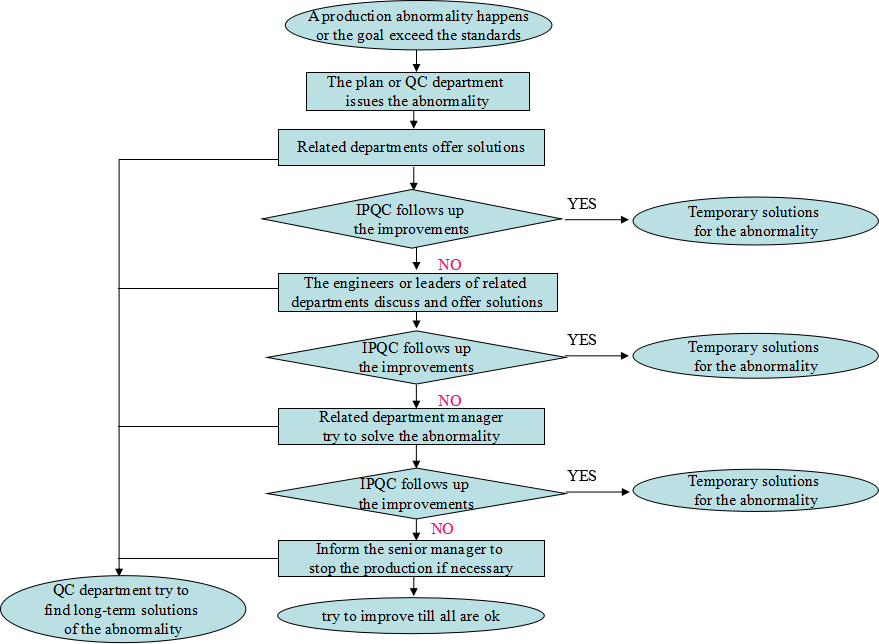

E. The handling process of a production abnormality:

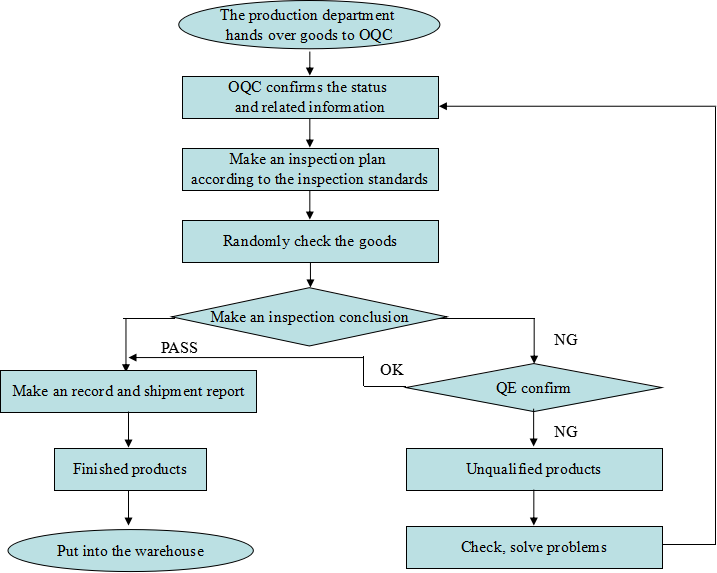

F. The inspection process before shipment: